Model A Primary Crusher. Parallel shaft gearboxes drive coarse or fine grind output. Coarse-ground materials 1-4". Fine-ground materials 1/2-2". Fine grind increases output. Minimizes wear and additional processing by secondary/tertiary grinders. Available with coarse and fine grind options. Ductile iron discs mounted on an 8-inch square

Learn More

Primary Crusher For Coal Sample Prepartion - FENGCHAN heavy Station Essa JC5000 primary jaw crusher for sample station and screw type coal sample crushing machine - DONNINA. Related Information. titanium ore mines in india hematite processing lne for ore european manufacturers of mobile crusher european type impact crusher.

Learn More

Download scientific diagram | Example of a Primary Crusher Product and Cyclone Overflow Size Distribution from publication: The appropriateness of the transfer size in AG and SAG Mill Circuit

Learn More

special needs of those who, for example, are visually limited or have limited reading proficiency. Examples of Alternative Formats shall include, but not be limited to, Braille, large font, audio tape, video tape, and Enrollee Information read aloud to an Enrollee by an Enrollee services representative. Alternative Payment Methodologies (APMs)

Learn More

May 06, Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher. After receiving the primary crusher crush the material and produce a new fresh reduced size of the source material. The primary crusher has only functioned up to that point. A secondary crusher comes into action and further reduces the size.

Learn More

For example, jaw crushers using this method of compression are suitable for For primary crushing with a reduction ratio of 6 to 1.

Learn More

For example, the calculation for PM would be: - 650 hp * 0.0007 lb/hp-hr = 0.455 lb/hr - 0.455 lb/hr * 1500 hours per year / 2000 lb per ton = 0.34 TPY B. Rock Processing Operations Point ID lb/hr Description Process Rate TPH Factor lb/ton Control Efficiency PM Emissions TPY

Learn More

Primary Crusher Example - manufacturer, factory, supplier from China. Industrial Manganese Steel Jaw Crusher Spare Parts. Well Transported Manganese Steel Jaw Crusher Spare Parts. Stone Crusher Simple Structure Vibrating Feeder. Iron Ore Slag Rod Mill Crusher Machine.

Learn More

China Primary Crusher Example Manufacture, Visit Here to Find the Primary Crusher Example That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd.

Learn More

This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard

Learn More

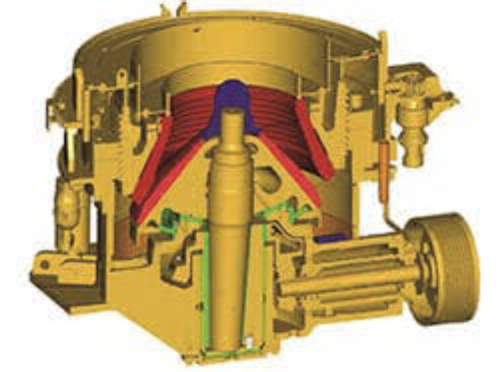

5.1 introduction. gyratory crushers were invented by charles brown in 1877 and developed by gates around 1881 and were referred to as a gates crusher [1]. the smaller form is described as a cone crusher. the larger crushers are normally known as primary

Learn More

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream

Learn More

A primary crusher plays an important role in a mineral processing plant. It reduces the size of large rocks wherein the smaller pieces are

Learn More

Crushers are classified according to the fineness with which they fragment the starting material. There are primary or secondary crushers (coarse finished

Learn More

The result is a 1-10 rating. For example, granite has a Mohs Scale rating of 6-7 whereas marble has a rating of 3-5. Abrasiveness. A jaw crusher is the most commonly used primary crusher. It uses simple technology to break down large blocks into smaller pieces. Their simplicity requires little engineering expertise to operate.

Learn More

Crushers are classified into three types based upon the stage of crushing they accomplish. These are (i) primary crusher, (ii) secondary crusher

Learn More

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process A typical example of primary crushing is reducing top-size from 900 to 200 mm In Selecting a primary crusher you need to ,

Learn More

Primary crusher options: impact crushers, hammer crushers, sizers & impact roll crushers Generation of a product ideal as feed material for vertical roller mills and ball mills Consistent high product quality Reduction on crusher load through pre-screening by

Learn More

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

Learn More

Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site. The gateway between extraction and processing, they bear the brunt of continuous operation, high feed volumes, and are subject to rock particles of extreme size variation and hardness. It is therefore vital that they are kept in top condition

Learn More