the patented Bar Grate Design for: • Strong resistance to abrasion. • «Self-protecting» design of grate. Our «extras»: cast FMR56 alloy + Xcc® to resist: • Wear. • Temperature. • Cracks. • Superiority coefficient: from 2 times better. Keep cool? Yes, we can! cooler grates Our «extras»: cast FMX250 alloy + Xcc® to resist:

Learn More

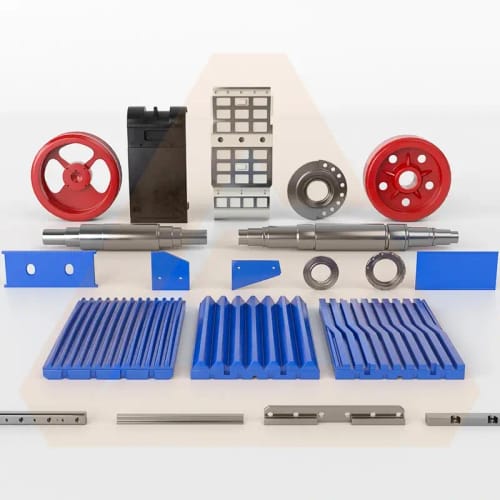

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan. Of these devices, grate bed is the most important part, mainly composed of overlapping rows of static and movable perforated grate plates.

Learn More

Oct 14, · Initial GRATE-KILN plants were designed with no heat recuperation systems and typically consisted of a two pass, downdraft drying and downdraft preheat grate cycle. A preheat bypass system was installed to complement the preheat off-gas supply so that these two streams delivered the required downdraft drying heat supply.

Learn More

This design delivers high degree of utilization and minimize overhaul maintenance costs due to eliminating

Learn More

Clinker cooling process is a complex process due to the vast number of adopted in the scaled conceptual design after an existing running clinker cooler.

Learn More

A design of Internal Model Control based PID controller for maintaining the under grate pressure of a grate cooler used in cement plants is presented in

Learn More

Speciality insulation systems for grate coolers that increase and maintain high The materials are designed to provide a full range of benefits in

Learn More

Not to mention the job that gives it its name: cooling the clinker before it's Which is why we have dedicated ourselves to enhancing cooler design since

Learn More

Jun 20, · 1. COOLERGrate Cooler is from Claudius Peters (CPAG) design , double stage Cooler with Drive fromHydraulic System For Grate 1 rated motor Hydraulic is 25 kW ,1750 rpm Grate

Learn More

It too can handle a large range of materials at high temperatures and can be supplied in a hybrid design in order to suit smaller plants without compromising on performance. Unax Cooler Compared to past grate cooler designs, this planetary cooler improves on durability, reliability and simplicity. Despite the Unax Cooler and rotary coolers

Learn More

Grate coolers are still essential to the cement industry in many countries. With our revised and improved Pyrostep² grate cooler design, we offer cement prod

Learn More

Ask any cement plant manager about the clinker cooler in his plant, The new erection concept, which utilises a modular design,

Learn More

Clinker is spread on the grate in a certain thickness after discharging into the grate cooler from the rotary kiln. The clinker progresses through the cooler by moving along the grate, and so the direction of the cooling air is at right angles to the direction of the clinker's movement. The grate cooler functions as a cross-current heat exchanger.

Learn More

FIELD: metallurgy. SUBSTANCE: grate of a grate cooler of shearing type includes a horizontal base and a working plate of straight-line shape with through passes for cooling air, which is inclined to it; at that, in the working plate there are cavities that in a vertical longitudinal grate plate section have the shape of triangles adjacent to each other so that alternating cavities and

Learn More

Fons Delta Cooler has been designed in a very smart and compact way; with this compact design, it can respond to the needs of each cement plant separately.

Learn More

In recent years, a large number of methodologies for the optimal design and control of grate cooler have been developed, which can be categorized into two broad types. One is to propose mathematical models of the clinker cooling process, the theoretical foundations of most of which are based on convection heat transfer principle [8] and porous

Learn More

between cooler and clinker stock especially for applications with grate coolers. The design allows the Pan Conveyor to be arranged underneath the whole cooler length and to collect the fines from the dust collecting hoppers same as the clinker from the crusher. Installed underneath the clinker stock in combination

Learn More

Grate Cooler Industrial Clinker Cooler is extensively used to cool the clinker and extracted heat from hot clinker is supplied Acknowledged for its optimum specific grate load, this ensures lower heat consumption. are then joined together for achieving maximum recuperation of heat. Moreover, the cooler operates with no risk of "Snowman"

Learn More

Grate cooler consists of upper case, lower case, lower frame, grate bed, hydraulic transmission device, grate bed support device, clinker crusher, automatic lubrication device, and cooling fan.

Learn More

Horizontal and inclined grate coolers are usually designed for cooling clinker from rotary kilns in cement plants. The cooler is normally positioned below

Learn More