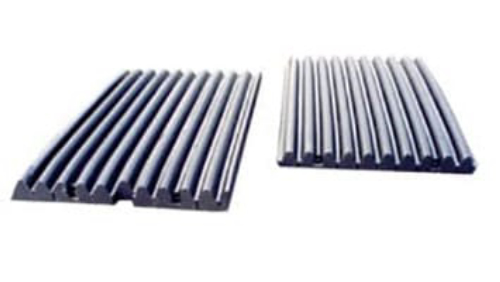

The jaw crusher liners need to change before they are worn through, in order to avoid damage to the crusher components. Different types of jaw crushers, the situation is different. Such as C105 and C3055, the jaw dies design on the ends is different. The locking wedges on these crushers are located behind the jaw dies rather than at the top of

Learn More

Wheel-type Mobile Crusher,Cone CrusherImpact Crusher,Heavy Hammer Crusher,European The customer is satisfied with the efficiency of the European version of jaw crusher and vibrating 2020-11-26 · Lead and zinc ores are the most important natural raw materials widely used in

Learn More

Selection depends on nip angle needed for the feed material, wear crusher liner plate At The Best Prices .com. Plate Crusher Liners Mn18Cr2 Manganese Steel Jaw Plate Tooth Plate Teeth Plate Casting For C145 Jaw Crusher Wear Liners. ,500.00-,000.00/ Piece. 1.0 Pieces (Min. Order) 3 YRS CN. Supplier. 5.0 (2) |. "satisfactory business".

Learn More

Jaw crusher liners High-quality jaw and cheek plates. Wear material that increases productivity. Austenitic manganese steel is the industry standard material for jaw crusher liners. High Manganese Steel Jaw Crusher Liner Plate, Size. High Manganese Steel Jaw Crusher Liner Plate, Size: 4-4.5 Feet (Length), for Crusher Machine

Learn More

jaw crusher liner material Jaw Liners. Crusher Wear Parts is an industry leader in supplying the best jaw liner parts for a specific application. We offer OEM as well as specialty configurations. We have decades of experience in supplying wear parts to the aggregate and mining industries. We conduct wear studies to evaluate which jaw liner

Learn More

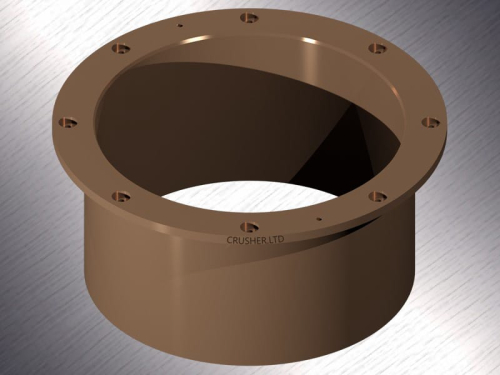

Jaw Liner is important to having quality finsihing and pefect fitting with jaw stock and frame,espeically the machining area of the back side are required pefect fitting with assembly to have less vibration, Minyu MCC40 /MCC1000 Combined Cone Crusher Material : Mn18cr2 /Mn13Cr2 Crushed Material: Granite Applications: Aggregates and Gravel

Learn More

The jaw crusher is usually made of cast steel because it is such a heavy-duty machine. Its outer frame is generally made of cast iron or steel. While the jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese steel, or Ni-hard (a Ni-Cr alloyed cast iron).

Learn More

High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn More

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and mov- able jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing.

Learn More

crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase the percentage of contact area against the jaw dies

Learn More

This material just suits wide tooth or super tooth jaw plates, not suit shape tooth jaw plates. Alloy Steel Crusher Jaw Plates These alloy steel jaw plates just use to magnetic separation stone, and the jaw plate weight less than 500 kg. Its elements: C 0.40% Mn 1.9% Si 1.4% S 0.012% P 0.016% The rest Mr. Nick Sun [email protected]

Learn More

Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco's products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry, manufacturers usually provide very few jaws die design options.

Learn More

Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit. This mechanism makes a movement aka four bar linkage movement. Through this movement, the movable jaw applies both pressure and friction forces to the material to be crushed.

Learn More

jaw crusher liner material HP300 DIRECTIONAL VALVE WSM06020Z-01-C-N-230A. jaw crusher construction Parts "4 1/4 SH locking nut homemade jaw crusher plans . vibrating gizzly bars GP100S CYL BUSHING GP100S crusher grizzly bars. Liner wear in jaw crushers. Jan 01, 2003 · 1. Introduction.

Learn More

The jaws are usually constructed from cast steel and fitted with replaceable liners, made from manganese steel, or “Ni-hard,” a Ni-Cr alloyed cast iron. A material is crushed in a Blake jaw crusher such that the average size of particle is reduced from 50 mm to 10 mm with the consumption of energy of 13.0 kW/(kg/s). What would be the

Learn More

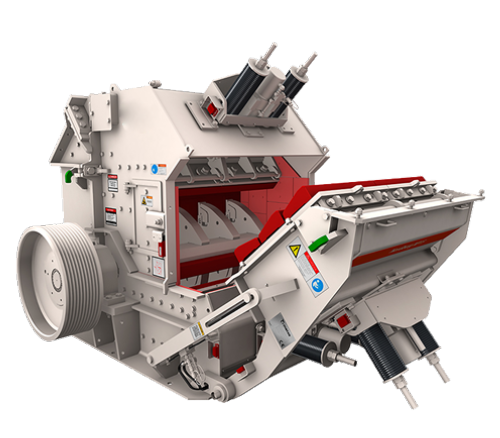

Counterattack plate breaking hammer is made of high chromium material. Compared with common high manganese steel hammer, it has the characteristics of high hardness, fine discharge and high wear resistance. The high hardness martensite matrix in the hammer can strongly support carbide particles, avoid the carbide falling off from the wear surface during the working process, and ensure the high

Learn More

Calculations for the jaw crusher chamber are somewhat simpler than in the case of the gyratory because the volumes included between the successive pairs of horizontal lines are rectangular in plan, whereas, in the gyratory we have to deal with annular volumes (actually, a descending spiral, rather than flat rings).

Learn More

Cement Plant. In Cement Plant, the wear resistant material of liners, grinding media, Crusher Hammer, Jaw Plates, Cheek Plates, etc. are widely used in different kinds of machines in the cement production process. PDF Jaw Crusher Cheek Plate Liner Design. The jaw crusher is a compression type crusher.

Learn More

Resminer Jaw Crusher Liners - Wear Resistance Manufacturer. Our Resminer jaw crusher liner is durable with extended life services. We have the highest quality rate of wear-resistant materials suitable for all crushing and grinding application industries. We have a lot of material choices for jaw crusher liners according to every application's

Learn More

We have a lot of material choices for jaw crusher liners according to every application's needs. TOP 5 Jaw Crusher Liner Manufacturers In China. For jaw crusher liner, they supply the following material Author Evaluation: This foundry is a very famous casting foundry in China. It can be said it is the Top one jaw crusher liner manufacturer.

Learn More

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers. Office - Toll Free: 888-852-9021 this material has a higher initial hardness of 248BHN. applications, 22% manganese can offer longer wear life, increased uptime and can outperform other grades of

Learn More